Izigxobo zokukhanya zethrafikhi ezihlanganisiweziyingxenye ebalulekile yengqalasizinda yesimanje yasemadolobheni. Lezi zinsika eziqinile zisekela izimpawu zethrafikhi, ziqinisekisa ukuthi ithrafikhi iphephile futhi isebenza kahle edolobheni. Inqubo yokukhiqiza izinsika zezibani zethrafikhi eziqinisiwe iyinqubo ethakazelisayo neyinkimbinkimbi ehilela izinyathelo eziningana ezibalulekile.

Isinyathelo sokuqala ekukhiqizeni isibani sethrafikhi esigqitshiwe yisigaba sokuklama. Onjiniyela nabaklami basebenzisana ukuthuthukisa amapulani anemininingwane kanye nemininingwane yezinsika. Lokhu kuhlanganisa ukunquma ukuphakama kwesibani, ukuma, kanye nezidingo zokuthwala umthwalo kanye nokuqinisekisa ukuthi sihambisana nawo wonke amakhodi nemithethonqubo efanele.

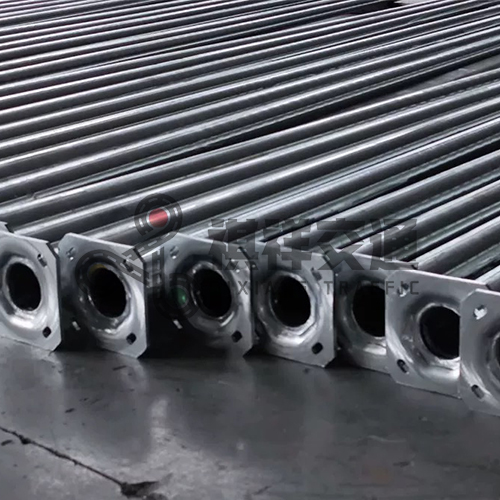

Uma umklamo usuqediwe, isinyathelo esilandelayo ukukhetha izinto ezifanele ipali. Yaziwa ngokuqina kwayo nokumelana nokugqwala, insimbi egayiwe iyona evame kakhulu ukukhetha izigxobo zokukhanya kwethrafikhi. Insimbi ivame ukuthengwa ngesimo samashubhu amade ayisilinda futhi isetshenziswa ekwakhiweni kwezigxobo zosizo.

Inqubo yokukhiqiza iqala ngokusika ipayipi lensimbi libe nobude obudingekayo. Lokhu kuvame ukwenziwa kusetshenziswa umshini wokusika okhethekile ukuqinisekisa ukusika okunembile nokunembile. Ipayipi elisikiwe libe selibunjwa bese lenziwa libe yisakhiwo esidingekayo esigxotsheni sesibani somgwaqo. Lokhu kungase kuhilele ukugoba, ukushisela, kanye nokwenza insimbi ukuze kutholakale usayizi kanye ne-geometry efanele.

Uma isimo esiyisisekelo senduku sesibunjiwe, isinyathelo esilandelayo ukulungiselela ubuso bensimbi ukuze kufakwe i-galvanizing. Lokhu kuhilela inqubo yokuhlanza nokususa amafutha ngokuphelele ukuze kususwe noma yikuphi ukungcola, uwoyela, noma okunye ukungcola ebusweni bensimbi. Lokhu kubalulekile ukuqinisekisa ukuthi inqubo yokufaka i-galvanizing iyasebenza nokuthi uqweqwe lunamathela kahle ensimbini.

Uma ukwelashwa kwendawo sekuqediwe, izinsika zensimbi sezilungele ukufakwa nge-galvanizing. Ukufakwa nge-galvanizing kuyinqubo yokumboza insimbi ngesendlalelo se-zinc ukuvimbela ukugqwala. Lokhu kufezwa ngendlela ebizwa ngokuthi i-hot-dip galvanizing, lapho induku yensimbi ifakwa khona ebhavini le-zinc encibilikisiwe emazingeni okushisa angaphezu kuka-800°F. Lapho insimbi isuswa ebhavini, ukuhlanganiswa kwe-zinc kuyaqina, kwakha ungqimba oluqinile noluhlala isikhathi eside lokuvikela phezu kwenduku.

Uma inqubo yokufaka i-galvanizing isiqediwe, kuzohlolwa okokugcina kwensika yokukhanya ukuqinisekisa ukuthi isembozo silingana futhi asinazo iziphambeko. Noma yikuphi ukulungiswa noma ukulungiswa okudingekayo kwenziwa kulesi sigaba ukuqinisekisa ukuthi insika ihlangabezana nezindinganiso ezidingekayo zekhwalithi nokuqina.

Uma isidlulile ekuhlolweni, izigxobo zokukhanyisa izimoto ezigqitshiwe zilungele ukuqedwa okwengeziwe njengehadiwe yokufaka, amabakaki, nezinye izesekeli. Lezi zingxenye zinamathiselwa esigxotsheni kusetshenziswa ukushisela noma ezinye izindlela zokubopha ukuqinisekisa ukuthi zifakwe ngokuphephile futhi zilungele ukufakwa endaweni.

Isinyathelo sokugcina enkambisweni yokukhiqiza ukupakishwa ngokucophelela kwezinsika eziqediwe ukuze zithunyelwe lapho ziya khona ekugcineni. Lokhu kuhlanganisa ukuvikela izinsika ekulimaleni ngesikhathi sokuthuthwa nokuqinisekisa ukuthi zilethwa ngokuphephile endaweni yokufakwa.

Ngamafuphi, ukukhiqizwa kwezigxobo zokukhanyisa izimoto ezigqitshiwe kuyinqubo eyinkimbinkimbi necophelelayo edinga ukuhlela ngokucophelela, ubunjiniyela obunembile, kanye nokunaka ngokucophelela imininingwane. Kusukela ezigabeni zokuqala zokuklama kuya ekupakishweni nasekulethweni kokugcina, isinyathelo ngasinye senqubo sibalulekile ekukhiqizeni izigxobo eziqinile nezithembekile ezidlala indima ebalulekile ekugcineni ukuphathwa kwezimoto okuphephile nokusebenza kahle ezindaweni zasemadolobheni. Ukuhlanganiswa kwezinto ezisezingeni eliphezulu kanye nobuciko bobuchwepheshe kuqinisekisa ukuthi izigxobo zokukhanyisa izimoto ezigqitshiwe zizoqhubeka nokuba yingxenye ebalulekile yengqalasizinda yasemadolobheni iminyaka ezayo.

Uma unesifiso sesibani sethrafikhi esigqitshiwe, wamukelekile ukuxhumana nomhlinzeki wesibani sethrafikhi uQixiang ku-thola ikhotheshini.

Isikhathi sokuthunyelwe: Jan-30-2024